Ultrasafe second-generation hybrid supercapacitor batteries change the game (2)

In this post, we outline how a simple device complements the inherent safety of hybrid supercapacitors and provides protection against abuse and external causes of fire.

One of the main concerns of lithium-ion batteries is safety, i.e. the risk of a battery fire. Safety risks are in general related to three factors:

- Probability of occurrence: how often and how likely can a battery start to burn?

- Severity: if a fire happens, how bad is it?

- Controllability: to what extent can measures be taken to prevent a fire or how can the consequences be mitigated?

Below we first elaborate on these 3 safety factors and analyse them shortly. Next, we show how our second-generation 18650Y and 21700Y cells handle these issues in a very simple and effective way by design, with no BMS needed.

In general, the probability of occurrence is relatively low. Battery-driven cars do not burn more often than e.g. gasoline or diesel cars. But the issues are the severity and the controllability. The severity of a battery fire is catastrophic. This is mainly due to the combination of a high amount of electric energy and the high inflammability and volatility of the electrolytes. If one cell has a thermal run-away, then the heat is often so high (with intense flaming) that often adjacent cells will overheat, and the whole battery with maybe 10000 cells will start to burn. Besides the heat (that can reach 4000 °C), the resulting fluoric gases are also very toxic. Such a fire is almost impossible to extinguish and can only be cooled with a lot of water. Residual electric energy can even reignite the fire, days later.

Hence, what about controllability?

A thermal run-away is always related to an escalating heat source. This can be internal (a short-circuit due to a growing dendrite) or external (overcharging, external short circuit, or cell skin penetration) of by exposure to high temperatures. A BMS can detect some of these conditions before they escalate but often not fast enough even if the BMS itself is working properly (sensors can be broken and software can fail). The reason is that short circuit currents can be very high (100’s of Amps) that in combination with the cell’s resistance can liberate kilowatts of thermal heat in seconds. This overheats the electrolyte turning it into a high-pressure and explosive gas. Hence, the controllability of a thermal run-away is close to zero. In the best case, measures can be taken to reduce the effects for example by encapsulation of the cells.

What does this mean for hybrid supercapacitor batteries?

Contrary to lithium-ion battery cells, powercapacitor cells use no symmetric redox reaction to store and release energy. This eliminates the major source of invisible dendrites that slowly grow. Hence, a powercapacitor will not start to burn unexpectedly and undetected. Secondly, powercapacitors have a low internal resistance (can be < 10 mOhm) and a wide temperature tolerance. (-40 to +80°C). This means that higher currents will not heat up the cells so quickly and that the internal chemistries will not so quickly break down when exposed to heat (which then often results in a higher internal resistance).

But even hybrid supercapacitors contain a lot of electric energy and volatile electrolyte. Two safety hazards remain: over-charging and sustained short-circuits. Both are externally induced. Over-charging can be due to an error in the charging system, for example when the charging voltage is too high. A short-circuit can only be caused by an operator’s mistake or during an accident. While all cells have a protective seal and weak points that open when the gas pressure becomes too high, often they open too late and a flame can still erupt in an oxygen-rich atmosphere. So how do our second-generation hybrid supercapacitors solve this without any BMS?

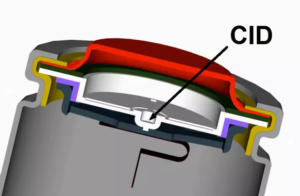

The benefits of a Current Interrupting Device

Simplicity is often the best remedy for reasons of robustness and resilience. Electronic safety devices can also fail because they increase the complexity whereby they become a source of hazards. Sensors can fail and software can be erroneous. Our 18650Y and 21700Y both have high energy densities (up to 130 Wh/kg) and a 10C power rating yet sustain over-charging and hard short-circuit tests with no fire or gas ejection. The key is a pressure switch, invisible to the eye, that interrupts the current when the pressure builds up too fast (typically at about 10 bar). Short circuit tests on a 2.4 Ah cell have shown that for example the cell delivers about 350 A or over 1 kW in heat in a few seconds upon a short-circuit, even before the cell skin reaches 60°C. When the CID triggers, a hybrid supercapacitor becomes an open circuit. The battery will lose some capacity, but the battery remains operational. A second feature is that it also opens to release gas in a second step at about 20 bar. At Altreonic we have done these tests. No fire, no explosion.

Simplicity is often the best remedy for reasons of robustness and resilience. Electronic safety devices can also fail because they increase the complexity whereby they become a source of hazards. Sensors can fail and software can be erroneous. Our 18650Y and 21700Y both have high energy densities (up to 130 Wh/kg) and a 10C power rating yet sustain over-charging and hard short-circuit tests with no fire or gas ejection. The key is a pressure switch, invisible to the eye, that interrupts the current when the pressure builds up too fast (typically at about 10 bar). Short circuit tests on a 2.4 Ah cell have shown that for example the cell delivers about 350 A or over 1 kW in heat in a few seconds upon a short-circuit, even before the cell skin reaches 60°C. When the CID triggers, a hybrid supercapacitor becomes an open circuit. The battery will lose some capacity, but the battery remains operational. A second feature is that it also opens to release gas in a second step at about 20 bar. At Altreonic we have done these tests. No fire, no explosion.

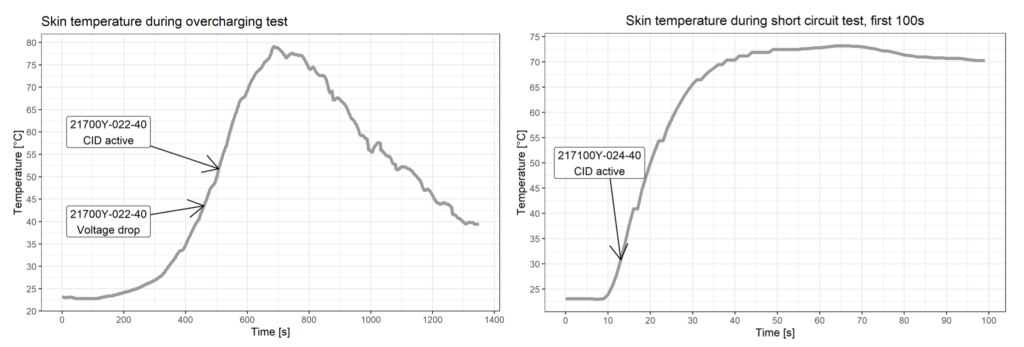

Testing the CID on a 21700Y cell

In order to verify the CID working, we performed abuse, hard short-circuit and overcharging tests on a 4.0V / 2.2 and a 2.4 Ah 21700Y cell. These have an energy density of 130 Wh/kg. The cells are rated for a maximum current of 25A (10C), hence the cell was first discharged with increasing currents. This triggered the CID after about 60 seconds at 45A (18C), resulting in an open circuit. Note that the cell was only cooled with a modest airflow. The cells were also subjected to a hard-short circuit over a high-current contactor. For the overcharging test, 8V was applied with a 10A (4C) current. The temperature is measured on the skin. There is a delay of about 7 to 10 seconds before internal high temperatures propagate to the skin of the cell.

In the overcharging test the voltage reaches a maximum of 5.26V, indicating a chemical breakdown while the cell is still charging. The current is still flowing but the safety device has not yet been activated. The temperature of the skin is 43.3 °C. 49 seconds after the voltage decline, the CID activates, and the skin temperature is 51.8 °C. This is after 500 seconds since the test started. The temperature reaches a maximum of 79.1 °C, 3 minutes after the CID interrupts the current. During a short-circuit test, the CID already triggers after less than 10 seconds. We measure 333 Amps while the temperature reaches a maximum after 50 seconds There is probably still an exothermic reaction ongoing in the cell after the CID has interrupted the current. All tests terminate with no gas venting, no explosion and no fire.

Protection for low power high energy hybrid supercapacitors

While hybrid supercapacitors are typically used in demanding applications with high requirements for power, these hybrid supercapacitors have modest energy densities, from 80 to 130 Wh/kg. For IoT applications, for example, high-energy supercapacitors (> 200 Wh/kg) are an excellent solution as they provide a wide temperature range with high energy density and long cycle life (> 20000 cycles). Such cells exist in different form factors, including pouch cells with no possibility to have a CID built-in. To protect such cells from accidental overcharging or short-circuiting small protection circuits can be used. These protect against over-voltage, short-circuits, and under-voltage with an active current switch.

Conclusion: Hybrid supercapacitors deliver unmatched power over a wide temperature range, but are also extremely robust and safe. Sustainability also means a long cycle life. Hybrid supercapacitors can deliver that for the lifetime of a system with no safety risks and zero maintenance.

Topics for our next newsletter:

- Passive thermal management for high-power batteries with hybrid supercapacitors

- Hybrid supercapacaitors for IoT applications

- New very high power hybrid supercapacitor: upto 2000A from a 4V 80Wh/kg cell

Recent Comments